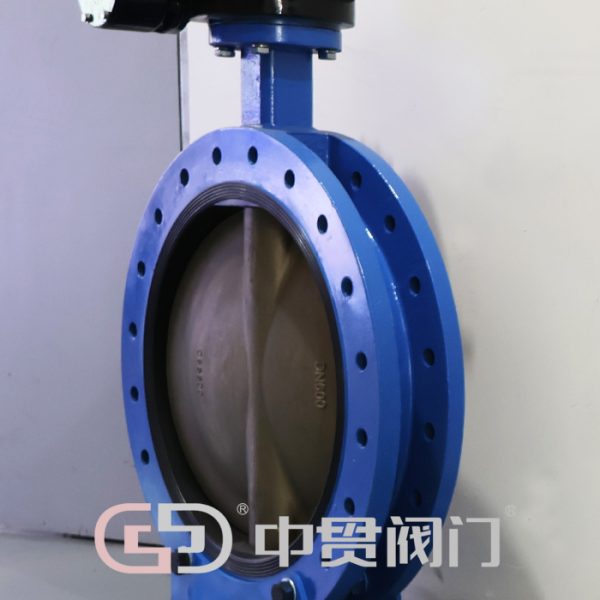

U Section Butterfly Valve

Structural Features

- Valve Body Design

The body of the U section butterfly valve is typically made from robust materials such as ductile iron, stainless steel, or carbon steel. This construction ensures high strength and durability, allowing the valve to withstand high pressures and harsh operating conditions. The U-shaped design of the body provides added structural integrity, making it suitable for both high-temperature and high-pressure environments.

- Disc and Shaft Assembly

The disc is a crucial part of the butterfly valve, responsible for regulating the flow of fluid. In U section butterfly valves, the disc is often made from corrosion-resistant materials like stainless steel or nickel alloys. The disc is mounted on a shaft that allows it to rotate 90 degrees to open or close the valve. The U section design ensures a tight seal when the valve is closed, minimizing leakage and ensuring efficient flow control.

- Seat Design

The seat in a U section butterfly valve is designed to provide a tight seal against the disc. It is usually made from resilient materials such as EPDM, NBR, or PTFE, which offer excellent resistance to wear and chemical attack. The seat is often replaceable, allowing for easy maintenance and extended valve life. The U section design helps to evenly distribute pressure across the seat, enhancing the sealing performance and reducing wear.

- Stem and Bearing Construction

The stem of the butterfly valve is connected to the actuator, which controls the opening and closing of the valve. In U section butterfly valves, the stem is designed to withstand high torque and provide reliable operation. Bearings are used to support the stem and reduce friction during operation. These bearings are typically made from materials with high wear resistance, ensuring smooth and long-lasting performance.

- Actuation Mechanism

U section butterfly valves can be operated manually, pneumatically, or electrically, depending on the application requirements. The actuation mechanism is designed to provide precise control over the valve position, allowing for accurate flow regulation. Manual actuators often include a handwheel or lever, while pneumatic and electric actuators offer automated control for more complex systems.

- Flow Dynamics and Efficiency

The U section design of the butterfly valve ensures minimal flow resistance when the valve is fully open. The streamlined shape of the disc and the smooth interior of the valve body contribute to efficient flow dynamics, reducing pressure drop and energy consumption. This design makes U section butterfly valves ideal for applications where maintaining high flow efficiency is critical.

- Installation and Maintenance

U section butterfly valves are designed for easy installation and maintenance. The compact and lightweight design allows for straightforward integration into piping systems, even in tight spaces. The valves can be installed between flanges using standard bolts, and the U section design facilitates quick and easy access for maintenance and inspection. Additionally, the replaceable seat and durable construction reduce downtime and maintenance costs.

Dimension

| SIZE | DN | Φ D | Φ D1 | b (mm) | L | N-Φ d | C | Φ G | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in | mm | A-series | B-series | A-series | B-series | A-series | B-series | (mm) | A-series | B-series | ||

| 2 | 50 | 150 | 120.7 | 17.5 | 43 | 4 – Φ 19 | F05 | 9 X 9 | ||||

| 2 1/2 | 65 | 180 | 139.7 | 20.7 | 46 | 4 – Φ 19 | F05 | 9 X 9 | ||||

| 3 | 80 | 190 | 152.4 | 22.3 | 46 | 4 – Φ 19 | F05 | 9 X 9 | ||||

| 4 | 100 | 230 | 190.5 | 22.3 | 52 | 8 – Φ 19 | F07 | 11 X 11 | ||||

| 5 | 125 | 255 | 215.9 | 22.3 | 56 | 8 – Φ 22 | F07 | 14 X 14 | ||||

| 6 | 150 | 280 | 241.3 | 23.9 | 56 | 8 – Φ 22 | F07 | 14 X 14 | ||||

| 8 | 200 | 345 | 298.5 | 27 | 60 | 8 – Φ 22 | F10 | 17 X 17 | ||||

| 10 | 250 | 405 | 362 | 28.6 | 68 | 12 – Φ 25 | F10 | 22 X 22 | ||||

| 12 | 300 | 485 | 431.8 | 30.2 | 78 | 12 – Φ 25 | F10 | 22 X 22 | ||||

| 14 | 350 | 535 | 476.3 | 35.4 | 78 | 12 – Φ 29 | F10 | 22 X 22 | ||||

| 16 | 400 | 595 | 539.8 | 37 | 102 | 16 – Φ 29 | F14 | |||||

| 18 | 450 | 635 | 577.9 | 40.1 | 114 | 16 – Φ 32 | F14 | |||||

| 20 | 500 | 700 | 635 | 43.3 | 127 | 20 – Φ 32 | F14 | |||||

| 24 | 600 | 815 | 749.3 | 48.1 | 154 | 20 – Φ 35 | F16 | |||||

| 28 | 700 | 925 | 835 | 863.6 | 795.3 | 69.9 | 44.5 | 165 | 28 – Φ 35 | 40 – Φ 22 | F25 | |

| 32 | 800 | 1060 | 940 | 977.9 | 900.1 | 79.4 | 46 | 190 | 28- Φ 41 | 48 – Φ 22 | F25 | |

| 36 | 900 | 1170 | 1055 | 1085.8 | 1009.6 | 88.9 | 52.5 | 203 | 32 – Φ 41 | 44 – Φ 25 | F25 | |

| 40 | 1000 | 1290 | 1175 | 1200.2 | 1120.8 | 88.9 | 56 | 216 | 36 – Φ 41 | 44 – Φ 29 | F25 | |

| 48 | 1200 | 1510 | 1390 | 1422.4 | 1335.1 | 106.4 | 65.5 | 254 | 44 – Φ 41 | 44 – Φ 32 | F30 | |

MORE REQUIREMENT AND MATERIAL INFORMATION, PLEASE DOWNLOAD THE CATALOG OR CONTACT US

Conclusion

U section butterfly valves are valued for their ability to provide precise flow control while maintaining minimal pressure drop. Their unique design and reliable sealing make them suitable for a wide range of applications, particularly where flow precision and structural integrity are paramount.