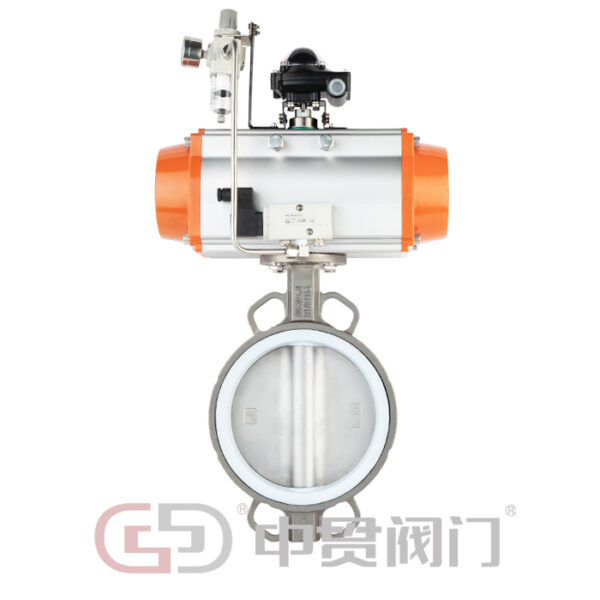

Pneumatic Actuated Butterfly Valve

A pneumatic actuated butterfly valve is a type of valve used for regulating the flow of a fluid (liquid or gas) in a pipeline. It consists of a rotating disc, which is positioned in the center of the pipe and rotates around an axis perpendicular to the flow. The valve is actuated by a pneumatic actuator, which uses compressed air to control the valve's opening and closing.

Here are the key components and features of a pneumatic actuated butterfly valve:

Butterfly Valve

- Body: The main casing that houses the valve components.

- Disc: The rotating element that controls the flow. It is positioned in the center of the pipe.

- Seat: The sealing component where the disc rests when the valve is closed, ensuring a tight shut-off.

- Stem: Connects the actuator to the disc, transferring motion to rotate the disc.

- Bearings/Bushings: Support the stem and reduce friction during rotation.

Features

- Quick Operation: Pneumatic actuators provide fast response times, making butterfly valves suitable for applications requiring quick opening and closing.

- Remote Control: The actuator can be controlled remotely, allowing for automated system management.

- Compact Design: Butterfly valves have a smaller footprint compared to other valve types like gate or globe valves.

- Low Pressure Drop: When fully open, the disc is parallel to the flow, causing minimal resistance.

- Versatile: Suitable for a wide range of applications, including water treatment, HVAC, chemical processing, and food and beverage industries.

Advantages

- Efficiency: Pneumatic actuators can handle large forces with a relatively small amount of compressed air.

- Safety: Pneumatic systems are generally safer than electrical systems in hazardous or explosive environments.

- Durability: Butterfly valves are robust and can handle a variety of fluids, including corrosive and abrasive ones.

- Cost-effective: Lower initial and maintenance costs compared to other valve types.

Maintenance

Regular maintenance is essential to ensure the longevity and proper functioning of a pneumatic actuated butterfly valve. Maintenance tasks include:

- Inspecting the Seat and Disc: Checking for wear and tear and replacing if necessary.

- Lubricating the Stem and Bearings: Ensuring smooth operation and reducing friction.

- Checking the Actuator: Verifying the pneumatic connections and ensuring there are no leaks.

Conclusion

By understanding the components, features, advantages, and applications of pneumatic actuated butterfly valves, you can make informed decisions about their use in various industrial and commercial settings