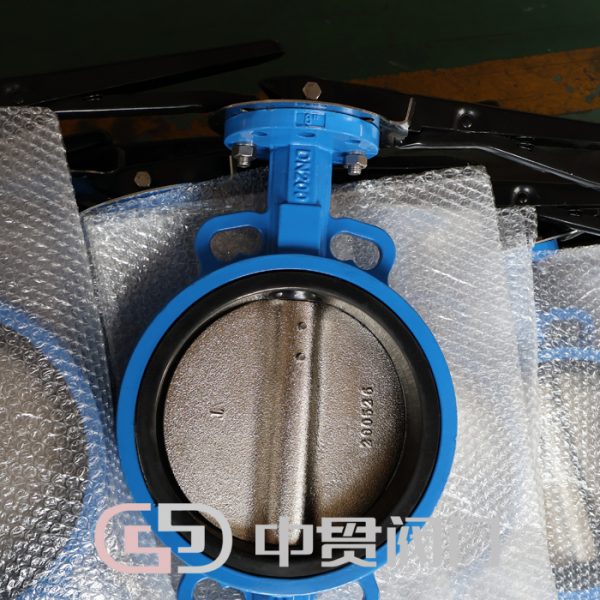

Nodular Iron Butterfly Valve

The rubber lining of butterfly valves is generally made of polymer materials such as polytetrafluoroethylene (PTFE), fluororubber (FKM), chloroprene rubber (NBR), etc. When selecting, it is necessary to select materials based on the characteristics of the working medium to ensure its good chemical stability and wear resistance.

Advantages of Nodular Iron Butterfly Valves

- Corrosion Resistance: Nodular iron resists corrosion from a variety of media, including acids, alkalis, and salt solutions. This property makes nodular iron butterfly valves ideal for long-term use in harsh environments.

- High Strength: Nodular iron exhibits excellent mechanical properties, stronger than traditional grey iron. This high strength allows nodular iron butterfly valves to perform well under high-pressure and high-flow conditions.

- Excellent Impact Resistance: Nodular iron has outstanding impact resistance, maintaining stability when subjected to shocks or vibrations, reducing the need for maintenance and replacement.

- Cost-Effective: Compared to more expensive materials, nodular iron is relatively cost-effective. It offers a long service life and low maintenance costs, making nodular iron butterfly valves an economically efficient choice.

- Suitability for Various Fluids: Nodular iron butterfly valves are suitable for a wide range of fluids, including water, gas, steam, and chemicals. This versatility makes nodular iron butterfly valves widely applicable across many industries.

Applications of Nodular Iron Butterfly Valves

- Water Distribution: Nodular iron butterfly valves are commonly used in water treatment plants, water distribution networks, and irrigation systems due to their corrosion resistance and durability.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, nodular iron butterfly valves regulate the flow of air and water, providing efficient control and durability.

- Fire Protection Systems: Nodular iron butterfly valves are crucial components in fire protection systems, ensuring reliable operation and long-term performance in emergencies.

- Industrial Processes: Nodular iron butterfly valves are used in various industrial processes, such as chemical processing, pulp and paper manufacturing, and mining, where corrosion resistance and durability are essential.

Dimesion

Conclusion

Nodular iron butterfly valves offer a combination of strength, corrosion resistance, and cost-effectiveness, making them a preferred choice in many engineering projects. Their reliability and durability make them suitable for a wide range of applications across industries.